GCL has formed by far the most integrated PV industry chains with the most intellectual property rights in the world. Relying on its continuous innovations and core-technology breakthroughs, GCL has made the transformation and upgrading from traditional manufacturing to intelligent manufacturing, utilized its production capacities and significantly improved the economy and efficiency of its photovoltaic systems. GCL has not only ended ChinaтАЩs PV industry dilemma of "two ends abroad", but is now playing an important role in promoting the use and the large-scale applications of solar energy in the world.

GCL targets at making PV-generated electricity affordable and inclusive for the public by its constant technology innovations in polysilicon, silicon wafers, cells, modules, system integration and photovoltaic power plants, continuous improvement of its management, regional layout and green energy certification systems.

шоУхЕЙф╝ПчЩ╝щЫ╗цИРчВ║хдзчЬ╛

чФих╛Чш╡╖чЪДцЩоцГашГ╜ц║Р

GCL Technology Holdings Limitedя╝ИStock Code 03800.HKя╝Й

A Global Pioneer in Research, Development and Manufacturing of High-efficiency PV Materials

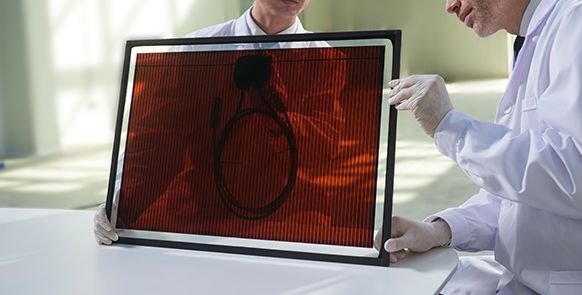

GCL Technology Holdings Limited is a global pioneer in the research, development and manufacturing of high-efficiency photovoltaic materials. It steers the wheel of high-efficiency photovoltaic materials technology and is a main technology driver as well as a leading supplier of polysilicon, granular silicon, silicon wafers and other photovoltaic products. GCL TECH adheres to staying market-oriented and staying specialized with strong R&D investments. From the improved Siemens method (GCL method) to the silane fluidized bed method (FBR) technology, GCL TECH has acquired a number of independent intellectual property rights and has been practicing like a trailblazer in the industry. Its silane fluidized bed (FBR) technology has won the carbon footprint certification in the field of photovoltaic raw materials both in China and in France, setting the lowest carbon footprint record of silicon materials at home and abroad.

GCL Technology Holdings Limited is a global pioneer in the research, development and manufacturing of high-efficiency photovoltaic materials. It steers the wheel of high-efficiency photovoltaic materials technology and is a main technology driver as well as a leading supplier of polysilicon, granular silicon, silicon wafers and other photovoltaic products. GCL TECH adheres to staying market-oriented and staying specialized with strong R&D investments. From the improved Siemens method (GCL method) to the silane fluidized bed method (FBR) technology, GCL TECH has acquired a number of independent intellectual property rights and has been practicing like a trailblazer in the industry. Its silane fluidized bed (FBR) technology has won the carbon footprint certification in the field of photovoltaic raw materials both in China and in France, setting the lowest carbon footprint record of silicon materials at home and abroad.

GCL System Integration Technology Co., Ltd я╝ИStock Code 002506.SZя╝Й

One-stop PV System Integration Service Provider

GCL System Integration Technology Co., Ltd. (GCLSIT) is committed to becoming the world's leading system integration service provider and aiming to build up one-stop integrated clean energy services systems. Its main business covers the research, development, designing, manufacturing, sales of PV high-efficiency cells, differentiated components, power station EPC, energy storage system integration and other related products. In 2021, the first phase of GCLSITтАЩs 60GW super AI factory in Hefei was officially completed and put into operation, of the worldтАЩs largest monolithic scale and at the lowest cost. From order-taking to customization, automatic production scheduling, production line matching and intelligent logistics, the comprehensive management of the entire closed-loop manufacturing process is now feasible with the highly intelligent big data. With GCLтАЩs worldwide brand effect, GCLSIT is actively exploring the global market and pursuing a long-term sustainable development.

GCL System Integration Technology Co., Ltd. (GCLSIT) is committed to becoming the world's leading system integration service provider and aiming to build up one-stop integrated clean energy services systems. Its main business covers the research, development, designing, manufacturing, sales of PV high-efficiency cells, differentiated components, power station EPC, energy storage system integration and other related products. In 2021, the first phase of GCLSITтАЩs 60GW super AI factory in Hefei was officially completed and put into operation, of the worldтАЩs largest monolithic scale and at the lowest cost. From order-taking to customization, automatic production scheduling, production line matching and intelligent logistics, the comprehensive management of the entire closed-loop manufacturing process is now feasible with the highly intelligent big data. With GCLтАЩs worldwide brand effect, GCLSIT is actively exploring the global market and pursuing a long-term sustainable development.

GCL New Energy Holdings Limitedя╝ИStock Code 00451.HKя╝Й

A Green Energy Provider

Specialized in PV Power

A subsidiary of GCL, GCL New Energy Holdings Limited(GCLNE) is a new energy enterprise that specialized in PV power generation. It also provides comprehensive management of the investment, development, operations and assets of power stations. Capturing the global trend of energy transformation, GCLNE is determined to supply the society with clean, safe, efficient and affordable green energy, specializing in PV power management. Accelerated transformation and upgrading via innovations and strategic cooperation are paving the way for GCLNE to become a green energy service provider. By the end of 2021, the accumulative installed capacity of photovoltaic power plants under GCLNEтАЩs operation and maintenance has reached 8.6GW.

A subsidiary of GCL, GCL New Energy Holdings Limited(GCLNE) is a new energy enterprise that specialized in PV power generation. It also provides comprehensive management of the investment, development, operations and assets of power stations. Capturing the global trend of energy transformation, GCLNE is determined to supply the society with clean, safe, efficient and affordable green energy, specializing in PV power management. Accelerated transformation and upgrading via innovations and strategic cooperation are paving the way for GCLNE to become a green energy service provider. By the end of 2021, the accumulative installed capacity of photovoltaic power plants under GCLNEтАЩs operation and maintenance has reached 8.6GW.

GCL Black Technology тАУ PV Products

FBR Granular Silicon

GCL has been seeking diversity in the development of polysilicon product technology. The FBR method for granular silicon production is the fruitful result of over-ten-years efforts, of which GCL owns 100% intellectual property rights. The FBR method has enabled the mass production of granular silicon and brought about a production capacity of 30,000 tons. Compared with the traditional improved Siemens method, the FBR method bear significant advantages: lowering the investment of a new factory by 30%, reducing the comprehensive power consumption by 70%, and bringing down the carbon footprint by 75%. The sphere shape of granular silicon grantees good trafficking, and when Czochralski single crystals are fed, there is no problem of jamming, which enables smoother re-feedings. Wider use of granular silicon can advance the realization of тАЬCarbon NeutralтАЭ in the production end of PV industry.

147 patents, 2 international standards (SEMI), 3 national standards

The conversion efficiency of a single reaction is 99%, meeting the standard of N-type single products.

Xuzhou, Leshan and Baotou form a tripod of production bases, reaching a planned manufacturing capacity of 500,000 tons.

FBR granular silicon won carbon footprint certification both in China and in France, setting the world's lowest carbon footprint record.

Copyright┬й2023 yikemiya help@bjykmy.cn